The original photopolymer UV inks cured so quickly that they didn’t have time to spread out and form a thin film, so the image areas stood proud of the media. Coarser halftones looked and felt like sandpaper.

Over the years the ink formulations have been refined and techniques such as pinning have reduced this effect to the point that the smarter curing systems can be used to vary the smoothness level between high gloss and matt within the same image.

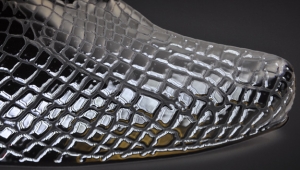

However, those sandpaper images can be a definite advantage if you exaggerate them. Because UV ink can be cured instantly after printing, it’s relatively easy to print on the same spot to build up layer on layer, giving a raised image that’s obvious to both the eye and to the fingers.

“The raised nature of a UV print – be it clear or process – has allowed tactile signage, or packaging proofs that require a Braille element or any decorative 3D effect to be created by simply printing multiple layers of ink in register,”said Duncan Jefferies, marketing manager for Mimaki’s UK agent Hybrid Services.

Rather like metallic effects, this raised imaging adds perceived value to the print, as the embossed appearance is associated with quality. As we also pointed out, combining metallics with raised ink simulates foil blocking, again a high value effect.

“Raised imaging gives a new effect,”pointed out Nick Decock, commercial marketing manager of Mutoh Europe in Ostend. “The luxury finish is certainly something printers are looking for, as it lets them charge a lot more than for regular work like posters and banners. It can be used for special effects, trophies, prototype packs and cartons – there are lots of possibilities.”

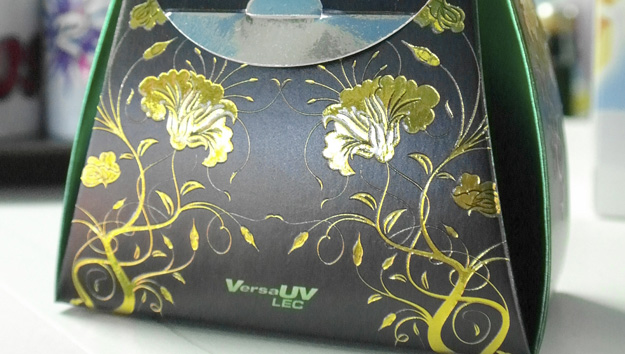

In theory any UV inkjet with a scanning head can do this, providing the Rip and controller are built that way. However, Roland DG was the first to make a big marketing point with this ability in 2008, when it introduced its first VersaUV printer-cutter, the 30 inch roll-fed LEC-300. This was replaced by the faster LEC-330 and the even faster and wider 54 inch LEC-540. It can build up layers of clear ink to form a pattern embossed effect, or it can create textures by using a greyscale image in the artwork file, where dark is “low (ie fewer layers) and white is high (more layers).

The raised layers are set up and controlled by the Rip, in this case Roland’s own VersaRIP which is bundled with all of its printers. Setting up is similar to creating a cutting path for the printer-cutters – a specially named layer is created in the original image file (which is most likely a PDF), which is then detected by the Rip and assigned to the clear ink.

BrotherJet shows off different texture effects using black UV cured ink

According to Jefferies, BrotherJet has been able to produced raised images singe the mid-2000s, although it has never made such a big thing of it as Roland did in 2008. The process is exactly the same as Roland’s building up multiple layers of ink by curing each layer.

The BrotherJet ArtisRIP software enables up to nine layers to be printed automatically to create the raised effect. It claims this requires minimal operator intervention or indeed file setup. By using a greyscale ‘height map’ for the clear layers, variable textures and domed effects can be created. BrotherJet’s UV printers range from the small BR-U1800 and U4880 flatbed models, to the big BR-7880 and BR-9880 flatbeds. these are the new small A3 flatbed BR-U1800 printer.

Mimaki produced this sample of Braille on signage, building up multiple layers of black UV-cured ink

This idea has sometimes been extended into the creative sphere, with raised imaging used for illustrations in Braille books as well as museum and gallery signage and descriptive labels. Using a digital print technology makes this possible for one-offs, temporary signage or short runs at low cost, compared to using metal dies to emboss the images.

Although most people will think of print as a planographic process, meaning its images are flat, metal dies have been used for centuries to add a 3D element to the surface.

Digital printing can now emulate that in ways that would be technically impossible, or too expensive for traditional dies, with the added benefit that there are almost no preparation costs, no special presses, and every copy can be different. The creative potential of raised print is on the up and up.

clear ink to form a pattern embossed effect, or it can create textures by using a greyscale image in the artwork file, where dark is “low (ie fewer layers) and white is high (more layers).